*Sorry,

this

series is sold

out.

Due

to

my current

backlog, I am

only accepting

orders for

full house

customs.

C.T.

Brian

Custom

.45 Commander Review

My

desire for a

C.T. Brian custom

pistol began the

day I received my Jan/Feb '97 issue

of American Handgunner. Tim's customization of a Colt

Commander

was the

cover story.

Of course the review was accompanied by dazzling photos that only

Ichiro Nagata is capable of.

That beautiful Colt caught my eye like no other custom 1911 had,

and I mentally filed Tim’s name as the one I would choose to

build me a

true masterpiece someday, an heirloom if you will. After

years of

waiting, I finally decided

it was time for my own Brian Custom... and now its here!

About

Tim-

Worth noting here is that Tim is a perfectionist when it comes to the

pistols he builds.

There is no part of this gun that has not been modified by his hands

and files.

Every pistol that leaves his bench is of “best

grade”

quality. Tim only builds around a dozen or so

'full house' pistols per year – when you learn that

approximately

80 hours of his time was put into

building my “masterpiece”, you begin to understand

the low

production number.

His goal is to build only the very best, and this he does. His

attention to the smallest of details

is one of his trademarks. The best pistol that Tim has built

is

the one

in front of him right now –

constantly striving to better his skills and knowledge resulted in this

beautiful pistol

reviewed here. Comparing my pistol to the AH Colt he built in

1996

shows the improvements

time has brought to his craftmanship... and his work was Master grade

quality then.

I admit to be “slightly” biased, but I consider Tim

to be the

premier 1911 smith.

His craftsmanship combined with his keen eye for details blurs the line

that separates

art from pistolsmithing. Tim has raised the bar in the custom

1911 field

to a higher plateau.

Parts Used-

Parts Used-

Frame/Slide - Les Baer oversize

Barrel – Storm Lake Machine

Barrel bushing - National Match

Sights - BoMar rear, Brian front

Ejector - EGW oversized

Extractor - Wilson Bulletproof

Beavertail - Brown memory groove

Thumb safety - Brown wide/competition

Trigger - Videki

Hammer - Infinity

Sear - EGW Competition

Disconnector - Infinity Tri-Glide

Mainspring Housing - Colt arched

Slide stop - EGW oversized

Magazine catch - Brown extended

Guide rod - standard Colt

Recoils springs - Wolff variable rate

Grips- Hogue cocobolo

Barrel

and slide to frame fitting-

Building a best grade pistol requires not only the skills of a master

pistolsmith, but also the use

of only the best parts. Tim's preferred platform to build on

is a

Baer

frame and slide

with oversized rails. Quoting from Tim's catalog on his

procedure

for

fitting these

two components together: By

a combination of careful

machining

and hand fitting,

a very nice and tight slide/frame relationship is accomplished.

He

also includes

a note about maintaining reliability: As

with any close

toleranced slide/frame fit,

cleanliness is important for reliability to be maintained.

I

can

tell you there is no play

in the fit... its tight but not to tight.

A Storm Lake Machine barrel mated with an National Match bushing is

Tim's choice this time

when building my Commander length 45. He precisely fitted

both

barrel

and bushing. No slop or play

is detectable. I like the fact that Tim fit the bushing tight

enough

that a wrench is

required to remove it, but the supplied plastic wrench works just fine,

which is

important to me as my "finesse" with most anything mechanical leaves a

lot to be desired - the

blueing will last much longer since I won't have to resort to a steel

bushing wrench. Judging by

the targets shown below, Tim knows how to correctly fit a barrel to

maximize accuracy without

compromising reliability... as he told me, you

get the hang of

it after fitting

your first thousand.

The

Trigger-

Tim tuned the trigger to break at a very crisp 4.25 lbs. The

only

way I

can describe it is to state thats it feels

similiar to that of a finely tuned DA revolver trigger. Once

the

trigger pull

begins you can detect a slight “rolling” feel in

the

take-up, a touch I’ve not felt on a 1911 before.

Its very subtle and can really only be felt while slowwwwly working the

trigger. Another CT touch.

Every Master 'smith adds a few modifications to their work to set their

weapons apart from others.

These mods can be purely cosmetic or combine functionality and

cosmetics.

Either way it sets their work apart and gives their customers a little

something special while adding

to the pride of ownership.

Like the French cut border on the slide, Tim's modification to the

Videcki trigger

is purely cosmetic. But its tastefully done and adds to the

overall

beauty and uniqueness

that make up a Brian custom.

Notice in the picture the additional 4 smaller lightning holes Tim has

surrounded the Videcki’s

standard ones with. To further enhance their appearance each hole was

slightly beveled... giving the

industry standard aluminum trigger an eye catching polished look,

- a nice touch indeed!

Slide

details-

The

slide

catches

your full attention when you first examine this

pistol.

This is the most visible touch that seperates a CT Brian pistol from

all others.

The flats have been hand polished to a mirror shine.

The bottom portion of the slide has been beveled inward and matte

finished.

The beveling is a most distinctive touch to almost the same width as

the frame and...

The

slide

catches

your full attention when you first examine this

pistol.

This is the most visible touch that seperates a CT Brian pistol from

all others.

The flats have been hand polished to a mirror shine.

The bottom portion of the slide has been beveled inward and matte

finished.

The beveling is a most distinctive touch to almost the same width as

the frame and...

Tim describes this much better than me, so...

Notice

there is a 'breakaway

angle' running

alongside the bottom. This is a precisely

machined cut that brings the bottom edge of your slide very close to

the

side of the frame. Now, instead of the side of the frame

'stepping out'

to the bottom edge of the slide, the slide now angles in to the

frame.

This

leads to a: less printing, and b: a better 'flow'. I know I

use

the

word

'flow' a lot. You'll understand the more you study your

custom. Anyway,

that

bottom 'breakaway angle' of the side will be bead blasted, just like

the

'non flats' of the slide. The remaining flat (which if you'll

notice,

runs out parallel with the uppermost point of the radius cut at the

lower end

of the slide), will be polished. The final effect is that,

when

viewed

from

the side, the upper radius of the slide shows the same amount of

'matte'

finish as does the 'breakaway angle'. The 'strip' between is

highly

polished, as are the flats of the frame. I'm sure I'm not

explaining

this well enough for you to visualize it properly, but I've been

doing

this on my full house customs for a year or so,

and the feedback from my customers has all been positive.

Tim's slide treatment is defintely different from what anyone else is

doing or has done. In addition

to reducing printing,

it is an eye catching addition that lets

you know you're handling

something special. I apologize to Tim for the poor quality of

my photography, believe me, it does not do justice to his artistic

talents.

A

well

executed

yet subtle French border separates the top radius of the slide from

the flats.

The width Tim cuts this at requires a bit of close examination to even

notice its presence...

a cosmetic modification that enhances the look of the pistol

without overwhelming the “whole of the pistol”

look.

A

Masters touch that adds much pride to

ownership of this pistol. The slide's radius is matte

finished. Moving

to the top of the slide

leads to another well executed cosmetic, yet functional

touch.

Tim has flattened and finely serrated the top at 40LPI for an

attractive non glare sight picture.

All sharp edges were broken very tastefully by old fashioned elbow

grease and files.

I much prefer this look to some of the radical

“melt-downs”

that some ‘smiths and

gunmakers offer today. The only sharp edges to be found are

the

serrations on the

front sight. Tim has given my pistol that bar of soap feel

without

compromising

the 1911s sexy lines!

A

well

executed

yet subtle French border separates the top radius of the slide from

the flats.

The width Tim cuts this at requires a bit of close examination to even

notice its presence...

a cosmetic modification that enhances the look of the pistol

without overwhelming the “whole of the pistol”

look.

A

Masters touch that adds much pride to

ownership of this pistol. The slide's radius is matte

finished. Moving

to the top of the slide

leads to another well executed cosmetic, yet functional

touch.

Tim has flattened and finely serrated the top at 40LPI for an

attractive non glare sight picture.

All sharp edges were broken very tastefully by old fashioned elbow

grease and files.

I much prefer this look to some of the radical

“melt-downs”

that some ‘smiths and

gunmakers offer today. The only sharp edges to be found are

the

serrations on the

front sight. Tim has given my pistol that bar of soap feel

without

compromising

the 1911s sexy lines!

Take

a look at

the fit of the BoMar

sight to the

slide. Not one sliver of daylight showing.

Tim carefully removed metal from the slide to enable the lowest

possible mounting of the

BoMar sight, so low in fact that a small amount of the hammer had to be

removed to clear the

rear of the sight blade! To complete the detailing of the

slide

Tim

serrated the rear to

match those of the BoMar. Notice Tim does not serrate the

extractor.

Whether or not to

serrate the extractor is debatable among ‘smiths.

Tim feels

that

since the

extractor is a replaceable part, it should be left un-serrated. I agree.

There

are a few

other of Tim’s

detailing that

need mentioning. Precise fitting of the grips.

The nicely executed dehorning

on the front of the slide. Its very subtle and easy to

overlook,

but

its there.

The ejection port was lowered and flaired to ensure complete

reliability.

All cuts are perfectly square. Even the recoil spring plug

and

cocking

serrations

did not escape Tim’s eyes nor files.

Details.

Details. Details.

Frame

details-

Featuring

hand

polished

flats and matte finished rounds, the frame was given the

full attention of Tim and his files. All edges were once

again

tastefully broken.

Tim perfectly executed 30lpi checkering on the front strap and main

spring housing.

Featuring

hand

polished

flats and matte finished rounds, the frame was given the

full attention of Tim and his files. All edges were once

again

tastefully broken.

Tim perfectly executed 30lpi checkering on the front strap and main

spring housing.

Father time combined with hand checkerer’s aches and pains

have

changed the way Tim now

accomplishes his checkering. He uses a mixture of homemade

tools

and

old fashioned hand files

now where once he did 100% of his checkering by hand. The

results

have

not changed.

Not a flaw is to be found. The cuts are straight and deep and

then the

diamonds are lightly

hand broken to provide the surest of grips without being too

sharp.

Perfect for a carry gun.

Take a look at the way Tim blends his checkering into the handsome

grips. One detail you cannot see is how Tim has carefully

blended

the diamonds around the magazine well. Tim charges a premium

price for

his checkering... once you find out the time consuming process he uses

you’ll understand why – and once you have a CT

Brian pistol

in your hand, you’ll know it was money well spent!

Cameron

Hopkins

best described

Tim’s treatment of the Colt mainspring housing.

The

mainspring housing is a work

of art unto itself. Tim starts with an arched unit and blends

it

to the

frame

by filing it to match. The result is a

“sunken”

mainspring

that literally feels like

the gun was left in the sun to long and it melted into the frame.

True

perfection!

The beavertail was hand filed and fitted to give the highest grip

possible. Tim fits this safety so that only the slightest

amount

of

pressure is needed to depress it. A feature truly appreciated

by

me as

it

insures that even a poorly aquired grip by my

hand guarantees

the gun will fire.

The thumb safety was given similar treatment. Tim fitted the

oversized safety to the frame and then filed and recontoured

it to give it the most comfortable fit. Thanks to careful

filing

and

polishing, there is no "bite" to the thumb. On/off engagement

is

positive

without being too tight.

The thumb safety was given similar treatment. Tim fitted the

oversized safety to the frame and then filed and recontoured

it to give it the most comfortable fit. Thanks to careful

filing

and

polishing, there is no "bite" to the thumb. On/off engagement

is

positive

without being too tight.

The

slide stop

was not

overlooked. Its edges were

subtly rounded.

The modification that Tim made to the slide stops protruding pin has

become one of his signature “marks”. The

pin was

flattened

and recessed

to fit into its now chamfered frame hole. While the

likelehood of

the

slide stop

being accidently engaged during a gunfight is very slight, it is

something

that Tim saw happen just one time in one of the many advanced training

courses

he has participated in. That one time was enough, and being

the

sort of

man unwilling to tempt

Mr. Murphy more than necessary, Tim takes care of this in a very eye

pleasing way.

How

it shoots-

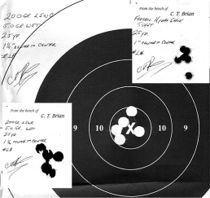

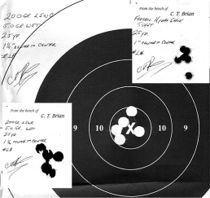

Tim included 3 targets shot from a Ransom Rest at 25yds (normally Tim

shoots at 50yds but those

Rocky Mountain cross-winds did not cooperate on range day).

Two ammo types were shot, Tim’s 200gr LSWC shop load along

with

230gr Hydra Shoks.

SOP for Tim is to include the average groups rather than the best...

I

make it a practice never to send a customer the 'smallest group

of the day'.

I found that to be refreshing and indictive of Tim’s true

character- completely honest.

Tim included 3 targets shot from a Ransom Rest at 25yds (normally Tim

shoots at 50yds but those

Rocky Mountain cross-winds did not cooperate on range day).

Two ammo types were shot, Tim’s 200gr LSWC shop load along

with

230gr Hydra Shoks.

SOP for Tim is to include the average groups rather than the best...

I

make it a practice never to send a customer the 'smallest group

of the day'.

I found that to be refreshing and indictive of Tim’s true

character- completely honest.

The "worst" 5 shot group using Tim's ammo measured out at 1-1/4", with

most of the groups averaging 1".

The Federal premium defensive ammo really shined in my

pistol.

The

largest group shot was 1".

On the whole, the HS typical group hovered around 3/4". No

question

about it, the man builds a shooter!

Finishing

touches-

A lot of old world craftsmanship

shows in Tim’s

pistols.

Though strictly cosmetic, the grip screws are

“timed”, that

is, the slots are

evenly vertical aligned. All pins are fitted flush with the

frame.

All lines are straightened and tooling marks removed.

This pistol was given Tim’s “Master Grade

Blue”

treatment. A time consuming process where only

hand polishing is used. You know its worth the extra money

when

your

pistol has,

to quote Tim, A

deep, dark and rich blue that never ceases to

amaze.

The finish is indeed beautiful, the flats having a true, almost black

mirror-like

appearance that contrast nicely with the matte finished non-flat

surfaces.

Summation-

Working together with Tim on this project was a pleasure. We

communicated frequently via

email, by phone when important details needed hashing out.

Though

we've

never met, a friendship

was forged, one that goes further than a business

relationship.

That

means a lot to me.

Here

are a few

quotes from Tim that

tell you a lot

about the man, his work ethic and his

thoughts about what his customers will

receive in a CT

Custom.

Billy,

I've got to say that as

much as you've

complimented my work, you

also deserve a great big pat on the back. You've been

excellent

to work

with.

A

true gentleman

who appreciates his

customers.

On

any custom I make, attention

to detail is of

the utmost importance.

Each and every part is individually modified until it achieves

absolute

perfection,

both aesthetically and ergonomically... The difference in my

work

comes

from making sure all of the parts and pieces that make up a pistol

‘flow’ together.

Flow

is a word

you'll hear often from

Tim. Its hard

to explain this with words...

to hold a CT pistol is to understand. What makes a Brian

pistol

unique

are the small, almost hidden

details of his work that you discover almost every time you examine his

work.

You

see, I believe in pride of

ownership. The

pride that comes from

knowing you own the very best...

Thanks

for your happiness and

faith in my work.

That, my friend, is my goal.

To be and offer only the best.

Meticulous

attention to details

coupled with his

skills, knowledge and a drive to make

each pistol better than his last, have positioned Tim at the top of his

profession. Not one to rest on his laurels, Tim will be

introducing a

limited edition

pistol aimed at those who choose a compact 1911 for concealed

carry.

This pistol features several innovative designs to the 1911 style

pistol which

enhance concealability. Look for this pistol to be reviewed

in

depth

in an upcoming 'GUNS' issue. The desire to be the

best and offer only the best still burns brighty inside Tim!

If

you want the

best 1911 that can be

had... you owe

it to yourself to get in touch

with C.T.

Brian. I'm

glad I

finally did!