| Home | Greeting | Catalog | Magazine Articles | Photos | Links | Contact | Ordering |

|

*The

CHOPPER |

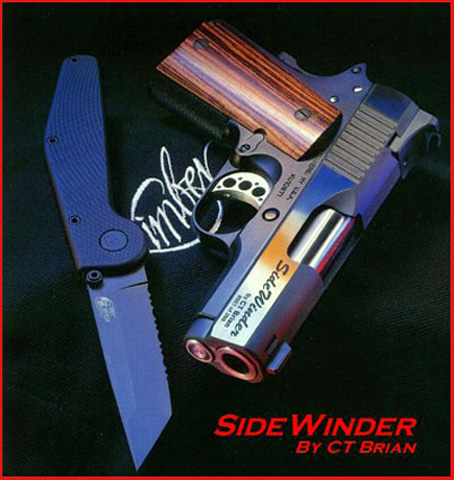

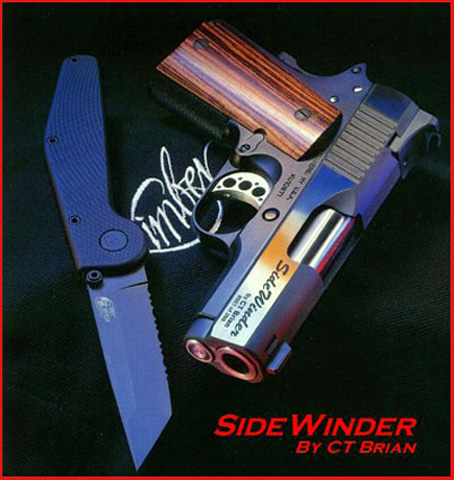

* SideWinder |

*Sorry,

this

series is sold out.

The ultimate in deep concealment!

October 2001 Guns Magazine Cover Story

Read it here!

The ultimate in deep concealment!

October 2001 Guns Magazine Cover Story

Read it here!

The

SideWinder may be small, but big

things come in tiny packages.

- Narrowed slide.

- Barrel throated & feed ramp properly angled and polished.

- Tritium

Slant Pro Fixed Sights.

- Ejection port lowered and flaired.

- Match grade extractor - recut, adjusted and polished.

- FlushFit hammer.

- FlushFit grip safety.

- Extended tactical thumb safety.

- Aluminum match trigger.

- Trigger job (4 lbs.).

- Front strap checkered at 30 lines per inch.

- Mainspring housing contoured and checkered at 30 lines per inch.

- Round butt of frame.

- Mill flat top of slide and serrate at 40 lines per inch.

- Detail complete pistol.

- Master grade blueing of slide and small parts.

- Hard anodizing of the frame.

- Smoothed and contoured grips.

- Thin slot grip screws.

- Special SideWinder engraving.

- Narrowed slide. Not enough to compromise structural integrity, but enough to lighten and slenderize it a bit.

- Barrel throated & feed ramp properly angled and polished: Just to make sure.

- Tritium

Slant Pro Fixed

Sights: The

sights

that come on

an Ultra

Carry are 'just

OK' in my book.

- Ejection port lowered and flaired: A bit lower and wider - again, just to make sure.

- Match grade extractor: Recut, adjusted and polished.

- FlushFit hammer: In my opinion, there is no need to ever touch the hammer on a 1911 style carry gun. I'm sure this will stir up some controversy, but if you think about it, you really can't come up with a logical reason why you would need to be able to manually manipulate the hammer of a carry 1911.

- FlushFit grip safety: By eliminating the hammer spur, one can further reduce the length of the pistol by eliminating the grip safety tang or beavertail. The FlushFit grip safety requires quite a bit of frame modification, but in return offers an extremely high handhold and greeater concealability. No hammer bite is possible, and printing is less of a problem. I've always liked the feel of a Browning Highpower in this area, and the FlushFit grip safety captures some of that feel, albeit thinner.

- Extented tactical thumb safety: I start with a wide thumb safety, then narrow and reshape it. When done, it just 'feels right'.

- Aluminum match trigger: Eliminates vertical movement, which adds consistency in trigger pull. The exact same each and every time.

- Trigger job: Four pounds. Crisp and clean. Perfect for a carry gun.

- Front strap checkered at 30 lpi: Using a special jig that I designed and built, I first perfect the radius of the front strap, then machine the initial lines, both horizontal and vertical. This makes for perfect alignment. Then, using a special file, each diamond is individually and painstakingly brought to point by hand. Finally, the area is gently bead blasted to take away any sharpness of the diamonds to prevent discomfort when firing. Time consuming, but there's just something about hand cut checkering that machine cut checkering can't duplicate. 20 and 25 line per inch checkering available on request.

- Mainspring housing contoured and checkered at 30 lpi: After replacing the plastic mainspring housing with a steel one, I again use a jig of my own design to radius the mainspring housing flush with the frame, machine the initial horizontal and vertical lines, then bring each diamond to point (by hand). Gently bead blasted, it gives a very nice, but secure, 'soapbar' feel. 20 and 25 line per inch checkering available on request.

- Round butt of frame: The bottom of the mainspring housing and frame is an area that can 'print' under a shirt or sweater. By carefully radiusing and rounding this area, with a file by hand, this problem is eliminated. It also makes the shorter grip of the Ultra Carry more comfortable when firing, too.

- Mill flat top of slide and serrate at 40 lpi: For a little something extra, the to of the slide is flattened and 40 line per inch serrations are added.

- Detail complete pistol: Some call it 'melting', but I use a file, not a grinding wheel. Every sharp edge is given an identical angles cut. In addition, all lines are straightened and all tooling marks are removed. The slide stop is given a 'makeover' and the slide stop hole is recessed. As with an custom I make, attention to detail is of the utmost importance. Each and every part is modified until it achieves absolute perfection in both looks and feel. Anybody can install parts. The difference in my work comes from making sure all of the parts and pieces that make up a pistol flow together.

- Master grade blueing of slide and small parts: No power bluffing wheels or such 'timesaving' devices are used. Hand polishing only. Elbow grease. The old fashioned way.

- Hard anodizing of the frame: Bead blasted to match the bead blasted areas (non flats)of the slide.

- Smoothed and contoured grips: Thinner than the norm. Smooth, for a more comfortable and snag-free carry. Unlike checkered ones, these won't snag or catch on your skin, shirt or sweater when using an IWB holster.

- Thin slot grip screws: Aligned, as they should be on any firearm of genuine custom quality.

- Special SideWnder engraving: Including the serial number of the 200 SideWinders that will be built.